In the current fiercely competitive industrial climate, adopting innovation is imperative rather than merely a choice. Artificial intelligence in manufacturing is driving this transformative movement, allowing companies to automate, optimize, and innovate like never before. Whether it’s optimizing production, anticipating maintenance requirements, or designing tailored products, the incorporation of AI in manufacturing is transforming the sector.

As the worldwide AI market in manufacturing is expected to exceed $20.8 billion by 2028, it’s evident that this technology is becoming permanent. Let’s examine how AI is transforming operations for leaders in the manufacturing industry, the benefits it provides, the challenges it presents, and the effective strategies to tackle them.

Key Benefits of AI in Manufacturing

| Enhanced Operational Efficiency | AI optimizes manufacturing workflows and automates repetitive tasks, significantly reducing cycle times and increasing overall productivity |

| Predictive Maintenance | By analyzing data from machinery, AI can predict potential failures and schedule maintenance proactively, minimizing downtime and reducing maintenance costs |

| Improved Product Quality | AI-powered quality control systems detect defects with high accuracy, ensuring consistent product quality and reducing waste |

| Supply Chain Optimization | AI enhances supply chain management by predicting demand, optimizing inventory levels, and improving logistics, leading to cost savings and better resource utilization |

| Cost Savings | Through efficiency improvements and waste reduction, AI helps manufacturers lower operational costs and increase profitability |

| Enhanced Safety | AI-driven safety systems can monitor and analyze workplace conditions in real-time, preventing accidents and ensuring a safer working environment |

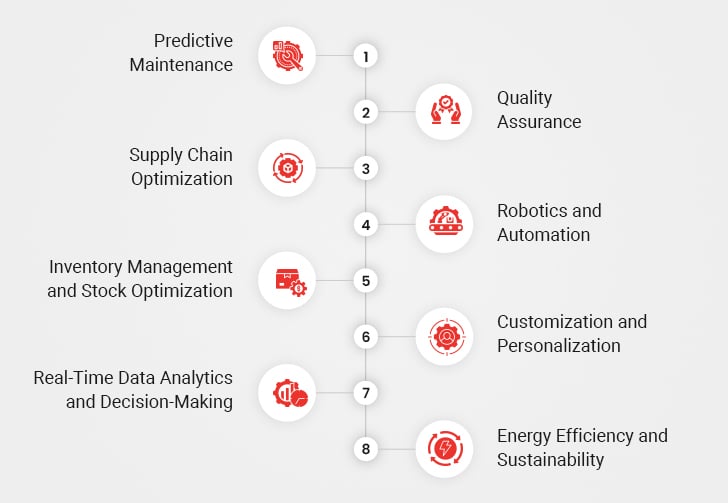

Real-World Applications of AI in Manufacturing

AI is revolutionizing the manufacturing sector, helping businesses optimize operations, enhance efficiency, and reduce costs. Below are some key use cases where AI has transformed manufacturing processes:

1. Predictive Maintenance

AI in manufacturing helps reduce unplanned downtime by predicting when equipment is likely to fail. By analyzing historical data, sensor readings, and performance metrics, AI systems can forecast maintenance needs, allowing businesses to perform repairs proactively. This reduces the need for costly emergency repairs and improves machine uptime. Artificial intelligence in manufacturing aids in minimizing unexpected downtime by forecasting when machinery is prone to malfunction. Through the examination of historical data, sensor measurements, and performance indicators, AI systems can predict maintenance requirements, enabling companies to conduct repairs in advance. This minimizes the necessity for expensive urgent repairs and enhances machinery availability.

How Companies are Leveraging Predictive Maintenance:

Siemens: Siemens has incorporated generative AI into its Senseye Predictive Maintenance platform, improving human-machine interactions and rendering predictive maintenance more intuitive and conversational.

Caterpillar: Through its Asset Intelligence Platform, Caterpillar utilizes data analytics to identify correlations that optimize performance, such as adjusting fuel meter readings to improve efficiency, leading to significant cost savings.

2. Quality Assurance

AI improves the quality control process by facilitating real-time data analysis to identify flaws in products during manufacturing. AI algorithms can analyze visual information from cameras or sensors, detecting irregularities or defects in materials or end products. This ensures better-quality products and minimizes the likelihood of defects being delivered to the customer.

How Companies are Leveraging Quality Assurance:

Bosch: Bosch employs AI-supported solutions in its manufacturing processes, implementing pilot use cases across various production facilities to enhance quality assurance and operational efficiency.

Tesla: Tesla integrates AI into its automotive innovation, utilizing machine learning algorithms to enhance manufacturing processes and product quality.

3. Supply Chain Optimization

AI optimizes supply chains by forecasting demand, improving inventory management, and predicting potential disruptions. AI-powered systems analyze historical sales data, market trends, and external factors like weather or geopolitical risks to suggest real-time adjustments in inventory and logistics.

How Companies are Leveraging Supply Chain Optimization:

Unilever: Unilever has developed an advanced AI-driven customer connectivity model that delivers an integrated end-to-end supply chain, driving growth and ensuring a continuous supply of products.

Amazon: Amazon’s AI-driven supply chain addresses challenges such as demand forecasting and logistics optimization, leading to reduced inventory costs and improved delivery times.

4. Robotics and Automation

AI-powered robotics is automating complex, labor-intensive tasks in manufacturing, improving speed, precision, and safety. These robots can perform everything from assembly to packing, working alongside human workers to enhance productivity while reducing the risk of human error.

How Companies are Leveraging Robotics and Automation:

FANUC: FANUC enhances industrial robots with deep learning, offering advanced manufacturing capabilities and transforming industries through automation solutions.

BMW: BMW has introduced advanced humanoid robots into its production lines, significantly boosting productivity and integrating seamlessly into existing manufacturing processes.

5. Inventory Management and Stock Optimization

AI systems use predictive analytics to optimize inventory levels by analyzing sales data and trends. By accurately forecasting demand and tracking stock levels in real time, AI ensures that manufacturers maintain the right amount of inventory, reducing storage costs and preventing stockouts.

How Companies are Leveraging Inventory Management:

Walmart: Walmart utilizes an AI-powered inventory management system to strategically place items across distribution centers and stores, optimizing the shopping experience and ensuring product availability.

Nestlé: Nestlé leverages AI to predict demand and optimize inventory levels, ensuring efficient supply chain operations and meeting consumer needs effectively.

6. Customization and Personalization

AI enables manufacturers to design and create products that meet specific customer preferences, enhancing the personalization aspect of production. By analyzing consumer data, AI identifies popular trends and recommends product modifications, helping businesses stay competitive in a fast-changing market.

How Companies are Leveraging Customization:

Nike: Nike employs Gen AI to transform product design and customer experience, offering personalized products that cater to individual preferences and enhancing operational efficiency.

Adidas: Adidas utilizes machine learning to anticipate future demand trends, learning from consumer design creations to better align products with market preferences.

7. Real-Time Data Analytics and Decision-Making

AI systems process vast amounts of data in real time, providing manufacturers with actionable insights to improve decision-making. This data-driven approach enables faster responses to operational changes, supply chain issues, or customer needs, ultimately driving better business outcomes.

How Companies are Leveraging Real-Time Data Analytics:

General Electric (GE): GE has invested in the Industrial Internet, connecting machines to the cloud and analyzing data to improve productivity and reliability across manufacturing processes.

Procter & Gamble (P&G): P&G collaborates with Microsoft to digitize and integrate data from manufacturing sites, enhancing AI, machine learning, and edge computing services for real-time visibility and operational efficiency.

8. Energy Efficiency and Sustainability

AI plays a pivotal role in improving energy efficiency and sustainability in manufacturing processes. By analyzing energy usage patterns and identifying inefficiencies, AI systems help companies reduce energy consumption and minimize waste, leading to more sustainable operations.

How Companies are Leveraging Energy Efficiency:

Bosch: Bosch is implementing generative AI in manufacturing to enhance energy efficiency and sustainability, developing software models to optimize production processes.

GE Vernova: GE Vernova has unveiled new AI-based software aimed at advancing industrial sustainability and operational goals, focusing on reducing resource consumption and carbon emissions.

These examples illustrate the diverse applications of AI in manufacturing, showcasing how leading companies are harnessing artificial intelligence to drive innovation, efficiency, and competitiveness in the industry.

Limitations of AI in Manufacturing

Despite its transformative potential, AI in manufacturing industry comes with challenges. Addressing these hurdles is vital for successful adoption.

I. Data Infrastructure

AI systems thrive on data, but many manufacturers lack the necessary infrastructure to handle large datasets. Establishing centralized, real-time data hubs is essential to overcoming this limitation.

II. Data Protection and Compliance

With AI handling sensitive operational and consumer data, robust cybersecurity measures are crucial. Adherence to regulations like GDPR and CCPA ensures both legal compliance and data security.

III. Standardization Challenges

AI integration requires standardization of processes and data formats. While this ensures clean data and easier scaling, it can restrict adaptability.

IV. Skill Gap

Implementing AI requires expertise in data science and engineering, which many manufacturers lack. Comprehensive training programs and partnerships with AI in manufacturing companies are essential to bridge this gap.

How to Overcome AI Adoption Challenges

Adopting AI successfully demands a strategic and phased approach. Here’s how manufacturers can tackle common challenges:

| Develop a Phased Adoption Plan | Start small with pilot projects to test AI solutions and demonstrate ROI before full-scale implementation. |

| Build Robust Data Infrastructure | Invest in technologies that enable real-time data collection, monitoring, and integration across systems. |

| Ensure Workforce Readiness | Provide employee training programs that focus on collaborating with AI systems, fostering a culture of digital fluency. |

| Partner with Experts | Collaborate with artificial intelligence and manufacturing specialists to ensure smooth deployment and ongoing support. |

Wrapping Up

The embrace of AI in manufacturing is not merely a futuristic idea—it represents both the current state and the future of the industry. From predictive maintenance to supply chain optimization, artificial intelligence in manufacturing is fostering unmatched efficiency, innovation, and business expansion.

Although issues such as data infrastructure and workforce preparedness remain, they can be tackled through strategic planning and collaboration with expert AI solution providers. By adopting AI in manufacturing industry, companies can boost operations, lower expenses, and maintain a competitive edge in the market.